High End - Coating Systems - EN

Coating Systems

Today's

demand on strength and surface finish requires a high quality cold-end coating.

Especially in light weight containers, it is important to prevent losses

of strength, furthermore it helps to increase the lifespan of the glass

containers. To achieve these effects, hot-end coating and cold-end coating

are applied sequentially. The still rough glass surface will be coated once

the annealing process is finished.

Today's

demand on strength and surface finish requires a high quality cold-end coating.

Especially in light weight containers, it is important to prevent losses

of strength, furthermore it helps to increase the lifespan of the glass

containers. To achieve these effects, hot-end coating and cold-end coating

are applied sequentially. The still rough glass surface will be coated once

the annealing process is finished.

The result is an effective protective coat to improve scratch resistance and lubricity. The efficiency in the filling process is optimized and the production will run smoothly.

Hot End Coating Systems with lifting device (Foldaway - System)

| Features | Benefits |

|---|---|

| Hood with lifting device | Decreasing production losses due to bottle jams, user friendly maintenance |

| Siemens drives and control systems | Optimal effects of operation due to synchronized drive systems and controlling |

| Remote maintenance | Solving software and set up problems online |

| Automatic stop of operation when device is lifted | Consumption reduction, safety-relevant features for machine operators |

| Monitoring of barrel weight and consumption | Reduction of consumption, prevention of sudden empty barrels |

| Operator panel with touch screen | Convenient handling and information at a glance |

| Integrable cooling and heating systems ( optional ) | Best effects of coating due to optimal temperatures in the hood, under consideration of bottle sizes, quantities and speed. |

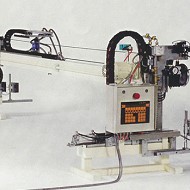

Cold End Coating Systems

The

spray device consist a beam with a linear unit, where the spray heads are

exactly positioned. To avoid spraying into the glass containers, the coating

is made below the bottle necks by precise dosages. The supply of the spray

nozzles takes place by flexible hoses from a fixed metering device. Operations

are controlled by PLC control unit.

The

spray device consist a beam with a linear unit, where the spray heads are

exactly positioned. To avoid spraying into the glass containers, the coating

is made below the bottle necks by precise dosages. The supply of the spray

nozzles takes place by flexible hoses from a fixed metering device. Operations

are controlled by PLC control unit.

The DPM Cold End Coating Unit is available as single - and twin axis systems

| Length of the beam | max. 5600 mm |

| Belt speed | max. 60m/min. |

| Atomizing pressure | 1-6 bar |